Why Appalachia Could Become the Silicon Valley of Industrialized Construction

The coal mining industry created a skilled labor force and resilient distribution network in Appalachia, but its decline has stranded assets and left many struggling to find work. As we consider how best to transition these workers to a post-coal world, it is clear there is a critical gap in American manufacturing they can fill.

Industrialized Construction, a rapidly growing industry in which modular or prefabricated building components are produced offsite, has the potential to increase manufacturing efficiency while decarbonizing construction, but it needs a strong workforce to achieve economies of scale and fill needs for more housing. By leveraging its forgotten industrial hubs and workforce for a new era of Industrialized Construction (IC), Appalachia can provide domestic jobs where they are most needed while addressing both the affordable housing and climate crises.

The Decline of the Appalachian Coal Industry

Over the last 15 years, the coal industry has seen a significant decline, particularly in Appalachia. Coal accounted for just 22% of domestic electricity generation in 2021, down from 48% in 2008. Although electricity from renewable sources has grown over 200% within the same time frame, much of that generation capacity was replaced by natural gas, which is still good news both environmentally and economically.

Industries that have historically relied on coal such as steel production are starting to adapt; large global steel producers are beginning to replace coal with gaseous alternatives. This has rippled upstream, particularly in Appalachia, where smaller mines have closed at a much higher rate than the larger and more efficient mines in the American West. For example, coal production has fallen 46% in West Virginia since 2008 and 25% from 2017-2021 alone.

Industry-Workforce Fit

The public and private sectors need to work together to catalyze a just workforce transition into a modern clean energy economy over the coming decades, especially in Appalachia. It is clear that the Appalachian workforce will need to adapt, but the good news is that mining occupations have left Appalachian workers with valuable and transferable skill sets. The competencies of former miners include “pipefitting, welding, computerized equipment operation, industrial maintenance, communications and electronics,” all of which are desired skills for manufacturing jobs. Moreover, the Appalachian Regional Committee (ARC) found that “The industrial machinery industry in Appalachia is a well-established, technology-intensive sector that is dominated by small and mid-size firms.” These mechanical and technical skill sets are increasingly in demand, and some companies are starting to catch on. From Richard Branson’s Virgin Hyperloop to the prominent clean energy developer Clearway Energy, companies have begun to invest in Appalachia and its greener future.

This is a good sign, but Appalachia still has yet to really settle on its new “industry-workforce fit”, defined here as the alignment of workers’ skills with an industry that needs those skills. Much like product-market fit, in which a product solves a pressing need or problem for a market, industry-workforce fit can create long-lasting, disruptive growth. It is often self-reinforcing, attracting compatible new businesses and skilled workers alike. Silicon Valley is a prime example of self-reinforcing industry-workforce fit, where large software companies attract tech talent and a strong flow of venture capital, which in turn attracts more large tech firms.

Appalachia, like many other American manufacturing hubs, once had an industry-workforce fit, but as the coal industry has declined, a generation of workers and their assets, resources, and know-how are being left behind. In 2021, West Virginia coal mine employment fell below 12,000, the lowest level since 1890. Just as self-reinforcing networks can grow rapidly, Appalachia shows how quickly this feedback loop can work in the opposite direction, displacing workers and, in turn, businesses when the industry is no longer viable.

It is imperative that Appalachia find and build a stable industry for its workforce in order to revive its economy and maintain its skills in manufacturing and industry. Luckily, there is an industry where the displaced coal workers could find an excellent industry-workforce fit within a sustainable America: Industrialized Construction.

Why Industrialized Construction?

Industrialized Construction can match the skill set of struggling coal towns with America’s need for sustainable, affordable housing. IC’s potential to reduce construction costs, time, and emissions makes the jobs it provides well-suited for a more efficient and environmentally friendly future. With the right environment and implementation, the use of modular construction projects can be built up to 50% faster and cost up to 20% less than traditional construction. Critically, IC has the potential to decarbonize buildings, which account for ~40% of energy-related carbon emissions. As the DOE writes, “Prefabrication in a controlled, factory setting has the potential to improve energy efficiency and performance while streamlining related code-compliance processes and better enabling the integration of advanced technologies. When integrated, this approach may reduce total energy use by 50 percent when compared to comparable site-built construction.”

In addition to its climate friendliness, IC is poised to be a major disruptor in construction, which has lacked the major efficiency gains of other industries over the past half-century: Projections show the modular construction market growing at a rate of 6% to $115 billion in 2028 from $76 billion in 2021.

While the progress that IC offers presents an incredible opportunity for American manufacturing and the climate, building the industry to competitive scale and quality will require financing capital, robust logistics and distribution networks, and a well-trained labor force. Demand in American construction as a whole already vastly outpaces supply, with up to 650,000 additional construction workers needed in 2022 just to keep up. At the same time, a nationwide housing shortage has doubled to 3.8 million units in the past decade. If this labor supply can be met, they will need to have or quickly learn specialized skills, even for traditional onsite construction. Workers from coal or other heavy industries can provide the capacity to fill this gap, enabling IC to scale and providing high-quality and compatible jobs to a region that needs it.

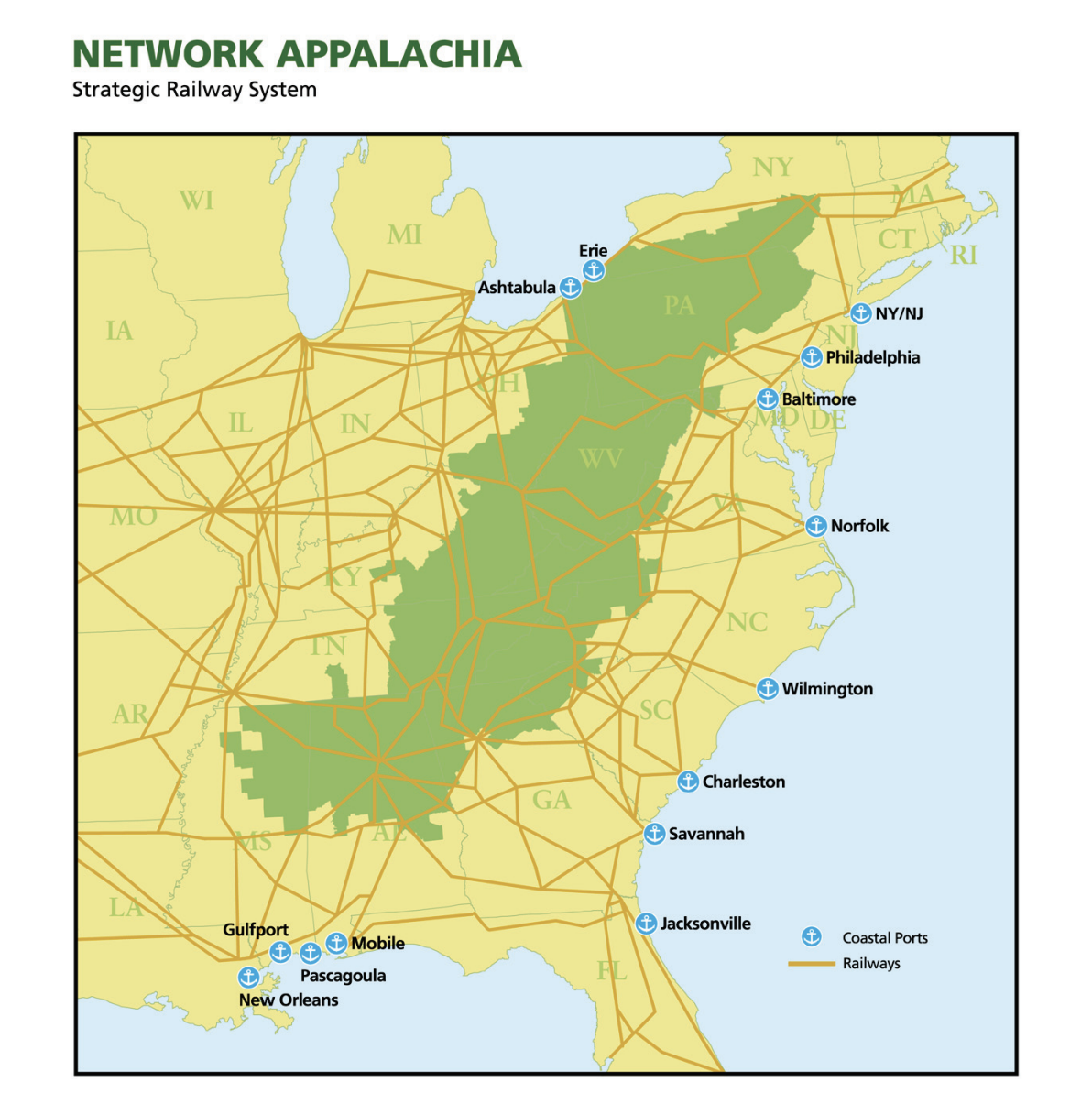

Appalachia as a Strategic Distribution Center

Industry-workforce fit is intrinsically linked with the underlying community, which must have a geography and built environment conducive to the industry and market needs. IC in Appalachia is no exception. Despite its rugged terrain, Appalachia’s coal and steel distribution system and ongoing transportation infrastructure development make its roads, rail lines, and waterways perfectly suited for use as IC distribution infrastructure. Such a partnership could revive a once-prosperous railroad network and enable energy-efficient shipping methods, especially for large and heavy building modules. A combination of mainline and shortline railroads link small towns or rural areas throughout Appalachia to the nationwide rail network and ports from NYC and Erie to Jacksonville and New Orleans, enabling high-speed and low-cost IC transportation.

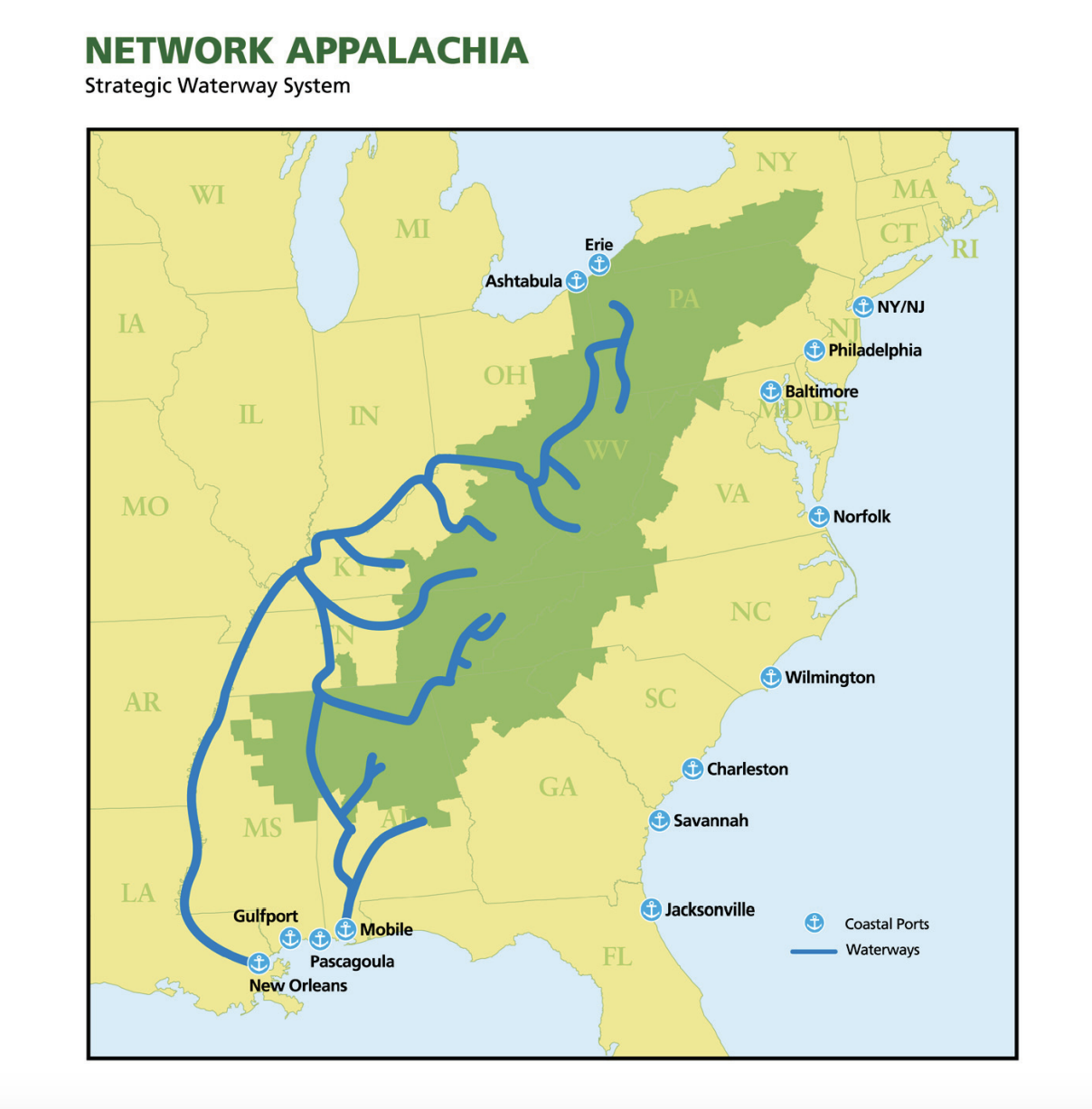

Further, although it lacks direct access to coastal waters, Appalachia boasts 1500 miles of inland rivers and waterways stretching from Pennsylvania and Ohio to Georgia, Alabama, and Mississippi. This network, which historically has moved raw materials like coal in bulk, would be well suited for shipping modular and panelized buildings across the Central and Southeast U.S. As an added benefit, research suggests that inland waterway and rail shipping generate 73% and 62% less emissions than trucking, respectively.

The government has also shown eagerness to invest in coastal and inland waterway transportation, a trend that is likely to accelerate as supply chain and climate problems grow increasingly urgent: in October 2022 the Biden-Harris administration announced nearly $39 million in grants for these “Marine Highways.”

Source: Appalachian Regional Commission

The Industrialized Offsite Construction Engine

There is clearly value in achieving industry-workforce fit for Industrialized Construction in Appalachia, but this synergy won’t happen on its own. A successful partnership would involve a complex network consisting of thousands of properly skilled workers, dozens of businesses, and quite a bit of capital. Additionally, modular construction is still a rapidly-transforming industry, with new research and development continuing to influence business and engineering decisions. Deep expertise will be crucial in ensuring the quality, economies of scale, and success of major IC projects in Appalachia. Thus, to attain an industry-workforce fit and build a thriving ecosystem, Appalachia will need to actively bring together a network of workers and companies, as well as academic and governmental institutions.

In support of this vision, ADL Ventures is creating the Industrialized Offsite Construction Engine or IOCE. Through leveraging its expertise in buildings, materials, sustainability, and venture creation, ADL is seeking to be the catalyst that starts, supports, and scales IC in Appalachia. By helping to commercialize research, training new workers and CEOs, launching new companies, and helping draw capital to the industry, ADL can help bridge the gap between the public, private, and academic sectors. Creating the IOCE will be a major cornerstone in ADL’s vision to rebuild and energize a clean and vibrant world. In doing so, we have the potential to create cleaner, higher quality, and more affordable housing, while making Appalachia the face of sustainable American innovation.

If you want to help us get this flywheel spinning, here is what you can do today:

Industry: Clean energy, construction, and manufacturing businesses should consider doing business in Appalachia, or starting partnerships with Appalachian companies and organizations, to take advantage of the skilled workforce and the numerous incentives and programs available to those doing business in the region. Help kick off powerful network effects and gain a first mover advantage.

Workforce: Whether you are a laborer in Appalachia or part of a workforce development organization, there is a huge amount of work to be done to enable large-scale retraining and industry transition. Additionally, there is an urgent need to quantify the existing skill sets and new skills to be taught, which in turn empowers skilled workers to pursue meaningful careers and become the driving force behind a clean American economy.

Join the NSF – IOC Engine: The Engine is already in operation. We have a DOE-funded accelerator that is working with clean and hard tech solutions. We have IOC related projects we are working on with some of 90+ industry partners today.

Reach out to ADL to discuss partnership opportunities with the Engine to be part of the new IC wave in Appalachia.